On Monday, August 28th, Caltrans Division of Construction Chief Ramon Hopkins issued a directive to Caltrans Resident Engineers that states that Tie (shipping) Wires in Dowel Bar Assemblies no longer need to be cut.

The CPD documents can be found here: CPD 23-6, “Tie Wires in Dowel Assemblies” [8/28/2023] https://dot.ca.gov/programs/construction/construction-procedure-directives-cpds

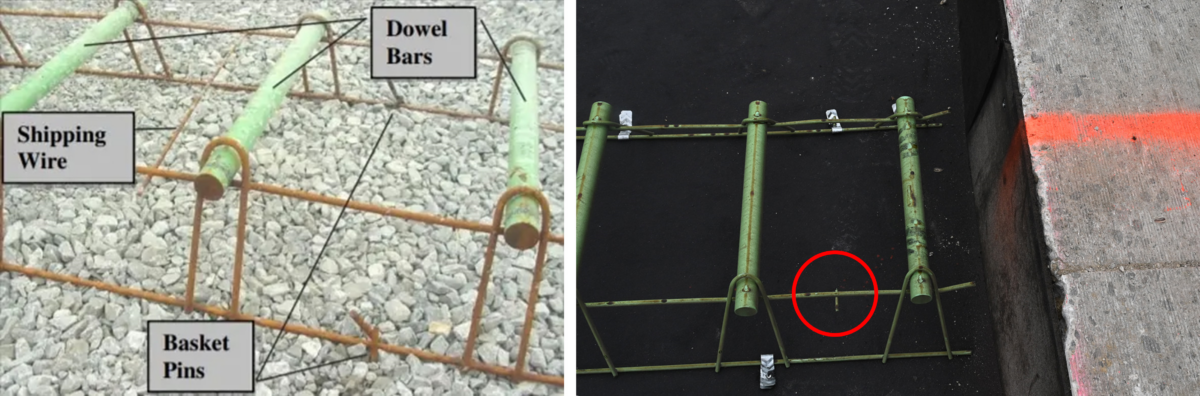

Shipping Wire, shown above on left, is also called Tie Wire and Temporary Spacer Wire. Photo on right shows shipping wire cut and removed.

This significant change in Section 40-1.03D “Dowel Bar Placement” of the Standard Specifications simply deletes the phrase, “cut and remove the temporary spacer wires.”

The No-Cut Tie-Wire Option Is Available Now!

The updated specification will be published in the 2024 Standard Specifications, but contractors have the option today to use the revised Section 40-1.03D specification for ongoing projects by submitting a no-cost change order request to the Resident Engineer.

This logical change was driven by the efforts of the Pavement & Materials Partnering Committee (PMPC) Concrete Pavements Subtask Group, which, as a part of the PMPC, brings together Caltrans and industry representatives to improve the quality and performance of concrete pavements throughout the State of California.

The change was spearheaded by SWCPA Executive Director Charles Stuart, based on input from SWCPA-member contractors. Concrete Pavements Subtask Group members working with Stuart to enact this change include, from Caltrans, Dulce Rufino Feldman – Chair, Deborah Yost, Mohammed Shamol, Deepak Maskey, and Arshad Vali; Bruce Carter from SWCPA; and Clay Slocum from California Nevada Cement Association (CNCA).

Why Was It There In The First Place?

Cutting tie wires became a requirement because they cause interference when taking measurements of the dowel position in the using magnetic tomography-type systems such as the MIT-SCAN2. Caltrans, however, does not specify taking measurements using this kind of equipment, so when this exception was brought to light, it was only logical to remove the requirement from the Standard Specifications.

Dowel bar assemblies, aka dowel baskets or cages, are manufactured with tie wires for improved stability during shipping and installation. The FHWA, in fact, recommends leaving the tie wires intact throughout the paving operation. The intact wires work to ensure the alignment of the dowel bar assemblies during placement and paving, which, in turn, enhances the long-term performance of the pavement.

Leaving the tie wires intact requires less labor from the contractor paving team, along with improving the rigidity and long-term performance of the pavement. It’s a smart, positive change that reduces construction schedules, saves money, and strengthens the concrete pavements, all great benefits to Caltrans and the traveling public.

Kudos and a tip of the hard hat to Caltrans and the PMPC Concrete Pavements Subtask Group for making this intelligent change.