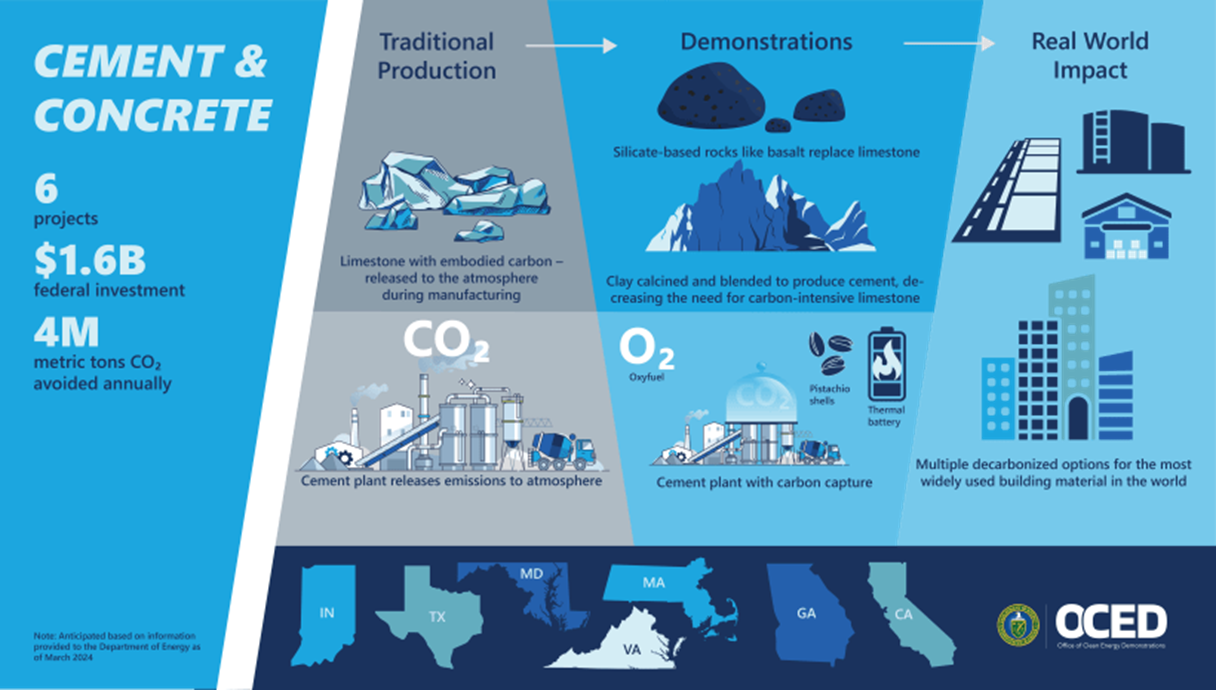

The Office of Clean Energy Demonstrations, a division of the Department of Energy, recently awarded six Cement and Concrete Projects $1.6 billion in an effort that will prevent more than four million metric tons of CO2 from being released into the atmosphere.

The Lebec Net Zero Cement Plant Project by National Cement Company of California, Inc. (NCC-California) will receive up to $500 million to produce carbon-neutral cement at its Lebec, California cement plant. Instead of using fossil fuels, the project will use locally sourced biomass from agricultural byproducts such as pistachio shells, replace clinker with a less carbon-intensive alternative (calcined clay) to produce limestone calcined clay cement (LC3), and capture and sequester the plant’s remaining approximately 950,000 metric tons of carbon dioxide each year. This project aims to demonstrate how a combination of decarbonization levers can drive emissions associated with existing U.S. cement production facilities to net-zero.

The plant upgrades will generate 20 to 25 new permanent jobs and improve air quality for the surrounding communities. NCC-California intends to establish a working relationship with Helmets to Hardhats, a non-profit organization that supports veterans transitioning out of active duty into the civilian workforce. Through these strategic collaborations, NCC-California aims to fund and offer diverse opportunities, including no-fee certification programs, non-credit courses, paid courses, internships, and job training opportunities. 100% of NCC-California’s hourly workforce is represented by the United Steelworkers.

The Deeply Decarbonized Cement Project by Brimstone Energy will receive up to $189 million to construct a first-of-its-kind, commercial-scale demonstration plant that will be designed to fundamentally transform the way cement is made. The project aims to produce 140,000 metric tons annually of decarbonized, industry-standard, ordinary Portland cement (OPC) and supplementary cementitious materials, and other co-products, using calcium silicate rocks and alternative production methods, to avoid producing more than 120,000 metric tons of carbon dioxide emissions per year. Further validating technology previously supported by ARPA-E, the demonstration project expects to reduce technical risks and prove demand to support the development of future industrial-scale decarbonized cement manufacturing facilities.

The other projects include:

Mitchell Cement team members flank Indiana Governor Eric Holcomb, DOE Under Secretary for Infrastructure David Crane and Heidelberg Materials North America CEO Chris Ward (back row: 10th, 12th & 13th from left)

The Mitchell Cement Plant Decarbonization Project, led by Heidelberg Materials US, Inc., plans to construct and operate an integrated carbon capture, transport, and storage system at their newly modernized plant located in Mitchell, Indiana, with an award up to $500 million. This project would capture at least 95% of the carbon dioxide from one of the largest cement plants in the nation and store it in a geologic formation beneath the plant property. This project expects to prevent two million tons of carbon dioxide per year from entering the atmosphere and would demonstrate a pathway to decarbonize existing cement plants in the U.S.

The First Commercial Electrochemical Cement Manufacturing Project, led by Sublime Systems, features plans to build a new, ultra-low carbon cement manufacturing facility in Holyoke, Massachusetts, with an award up to $86.9 million.

The Limestone Calcined Clay Cement Production Project, led by Roanoke Cement Company, has plans to demonstrate the ability to utilize widely available clay types to minimize the most carbon-intensive component in cement. This project would also help validate the market for calcined clays in a region with high demand for the material, while reducing the carbon intensity by an estimated 83%. The award is available up to $61.7 million.

The Low-Carbon Calcined Clay Cement Demonstration Project, led by Summit Materials, Inc., includes plans to construct four new calcination facilities in Maryland, Georgia, and Texas. This project would demonstrate the viability of displacing high-emitting limestone-based cement with a clay-based product in multiple geographies. Their award is up to $215.6 million.