Adjacent to Sacramento’s Cal Expo, the site of the California State Fair, the Interstate 80 American River Bridge was originally constructed in 1954 as separate northbound and southbound two-lane spans across the American River. In 1966, the 1.5-mile bridge was widened to three lanes in each direction. As no new structural support was added to the spans during the widening, the two new lanes were constructed with lightweight concrete, which enabled the expansion without overburdening the piers.

Aerial view on January 20, 2023 during a flood stage of the American River, with new pier construction at the top right. Photo by Mark Spicer.

Over the course of the past 70 years, transverse and longitudinal deck cracking, and spalling has developed, along with a high chloride content in the concrete deck surface. Erosion of the river bed around the foundation piles over the past seven decades created a separation between the bottom of the bridge footings and the river bottom, illustrated in the photo below, undermining the bridge foundation. All of these conditions spurred the need to rehabilitate the bridge deck, protect the abutments and piers from scour, and – before emergency repairs were needed – maintain the critical connection between downtown and eastern Sacramento.

Underwater view showing one of the exposed steel foundation piles. The bottom of the concrete bridge footing is at the top of the photo, with the river bottom in the background behind the pile.

American River Constructors (ARC), the joint venture (JV) of Granite Construction and California Engineering Contractors, was awarded the $131-million Parent Contract to construct the superstructure for the replacement of the existing bridge deck in three stages for Caltrans under a Construction Manager/General Contractor (CM/GC) contract.

A CM/GC contract is advantageous because it allows the contractor, during design and planning phases, to provide constructability reviews, value engineering suggestions, construction estimates, and other construction-related recommendations. It offers a lower risk profile for both the contractor and the owner while increasing the overall value to project stakeholders, promoting collaboration and value-adding feedback from the contractor.

Building the cofferdams involved placing the template (pictured in mid-crane-lift in the center of the photo), installing the sheet pile perimeter (bottom right), and then anchoring the foundation piles.

The total estimated project cost is $216 million and is funded by the State Highway Operation and Protection Program (SHOPP) and a Local Active Transportation Program (ATP) Grant.

Following an extensive Project Study Report in 2015 and an Environmental Impact Report in 2021, ARC received a preconstruction services contract that year for the project. Design documents were created from February 2021 through December 2022, and thanks to the CM/GC contract, construction was able to start in January 2022, concurrent with the ongoing design work.

The American River Bridge (ARB) Team of Caltrans and ARC conducted extensive research to ensure that sound pollution affecting adjacent neighborhoods would be minimized as much as possible. Environmental studies were also conducted to ensure that work in the river would not negatively affect fish and other wildlife, along with the flow of the American River.

Early in the day on August 2, 2023, two mixer trucks feed concrete into the pumping system that will deliver it to the new pier forms erected within the cofferdams. Photo by Mark Spicer.

Thanks to long-term relationships, the ARB Team was able to meet with all of the permitting agencies together and reduce the time to secure all of the required permits from approximately 18 months down to less than 12 months.

“The ARB Team accomplished the nearly impossible task of addressing all regulatory and environmental permitting issues that allowed us to start construction in the floodplain in 2022,” stated Granite Project Executive George Delano. “The communication, collaboration, and responsiveness with the various permitting agencies have been the key to that success. The team worked closely with the U.S. Army Corps of Engineers, coordinating our work with their efforts in armoring the levees along the river near the bridge. This ongoing communication enabled an accelerated approval process for all of the required permits from all of the involved agencies.”

Three Child Contracts, totaling $70 million, funded ARC’s initial work on establishing site access, vegetation clearing, steel piling and girder procurement, and bridge substructure construction.

This photo, shot later on August 2, 2023, shows the completed new piers on land (to the right) and the progression of the river pier construction (left) with a spider pump on the barge delivering concrete into the pier form in the cofferdam. Photo by Mark Spicer.

“The ARB Project Team has done an amazing job working together to deliver the initial projects, including weathering the unprecedented storms from multiple atmospheric rivers last winter,” George Delano explained. “It enabled us to hit the ground running on the current Parent Project. We had the girders erected before last Thanksgiving, and we’re well on our way to successfully completing the project in the first quarter of 2026.”

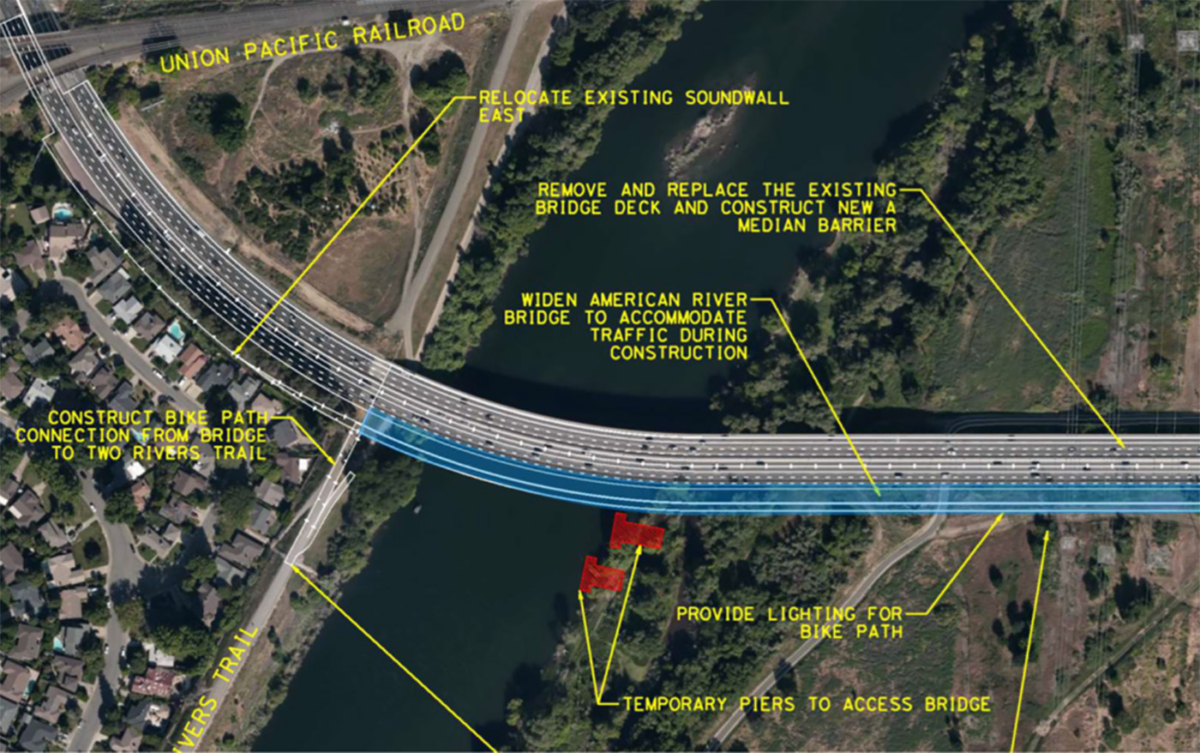

The overall scope of work includes:

- The removal and replacement of the existing concrete deck;

- The removal and replacement of the steel girder post-tensioning systems in spans one and two;

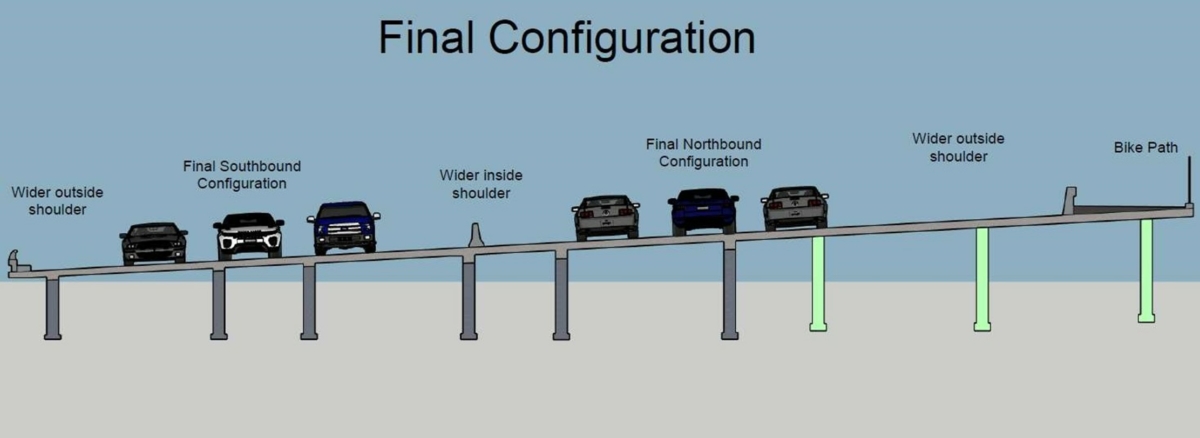

- Construction of the substructure that will support the widening of the bridge 54 feet to the east, expanding the shoulder to accommodate traffic-lane shifting during construction, minimizing back-ups;

- Installation of sheet piling around piers for scour mitigation;

- Construction of concrete catcher blocks for earthquake resistance;

- Construction of a Class 1 bike/pedestrian path on the bridge that will connect to existing bike trails; and

- Modification of existing sound walls.

Building new reinforced footings in the American River presented a unique set of challenges. First, work could not be performed in the river from June through October due to the run of steelhead and salmon up to their spawning grounds below Nimbus Dam at Lake Natoma.

With the Grinch keeping a watchful eye from the Granite bridge walkway, the last of the replacement deck pours takes place in December 2023. Photo by Mark Spicer.

Then, to build the new bridge substructure and supporting piers in the American River, cofferdams were constructed around the perimeter of the steel piling footprint beams to enable the environmentally safe placement of the concrete below the water level to create the new footings. To construct the cofferdams, floating barges were used to convey the 200-ton cranes, scissor lifts, and, later, the concrete pumps over water to the cofferdams for the pier construction.

Once the supporting piers were constructed, the residual surrounding water in the cofferdams had to be pumped out to avoid polluting the river. Walkways were built between the cofferdams, spanning 85 feet, enabling the spider outrigger pumps to be transported from one cofferdam to the next to pump out the contaminated water.

View of the project on January 18, 2024 with staging areas on both sides of the river, cofferdams in place, and barges in the river. Photo by Mark Spicer.

Cemex has been working with Granite and Caltrans to formulate an optimal mix design for the project, specifically for the concrete being used for the bridge deck, which needs to be lightweight, at 109 lbs. to 115 lbs. per cubic foot, air-dried at 90 days, with a compressive strength of 5,000 psi. The other concrete being used in the bridge is standard weight.

To achieve the right mix design for the 7,000 cubic yards of lightweight, crack-less concrete to be used on the bridge deck, Cemex experimented with seven different trial batches. What has emerged as the optimal mix design contains lightweight coarse aggregate, lightweight sand, cement, slag, shrinkage reducing admixture (SRA) that limits shrinkage to a maximum of 0.032%, water, and – per cubic yard – three pounds of macro fibers and one pound of micro fibers. Approval of the current lightweight mix design is expected by the end of this month, February, or early March. Completion of the project is scheduled for the first quarter of 2026.

Big thanks and a tip of the hard hat to Granite Project Executive George Delano for all of his kind assistance and contributions to this story.