Anyone who has driven I-5 through Santa Clarita, either down south from the Grapevine or north out of the San Fernando Valley, can see the growth that has blossomed in this region just up the hill from the sprawling Los Angeles megaplex.

Santa Clarita was the site of California’s first gold discovery in 1842 (yes, even before Sutter’s Mill), and the state’s first oil well in 1876, but its real fame came shortly after the turn of the 20th century when the movie industry discovered the region and turned it into the go-to location for filming Westerns. Some of Hollywood’s biggest stars, including Tom Mix, Gene Autry, and John Wayne, liked the area so much while shooting there, they moved to Santa Clarita.

Today, it is the third-largest city by population in Los Angeles County, and Santa Clarita continues to grow. With that growth, comes more homes, more businesses, and more traffic, so in order to relieve congestion and back-ups, Metro and Caltrans District 7 have initiated the I-5 North County Enhancements Project.

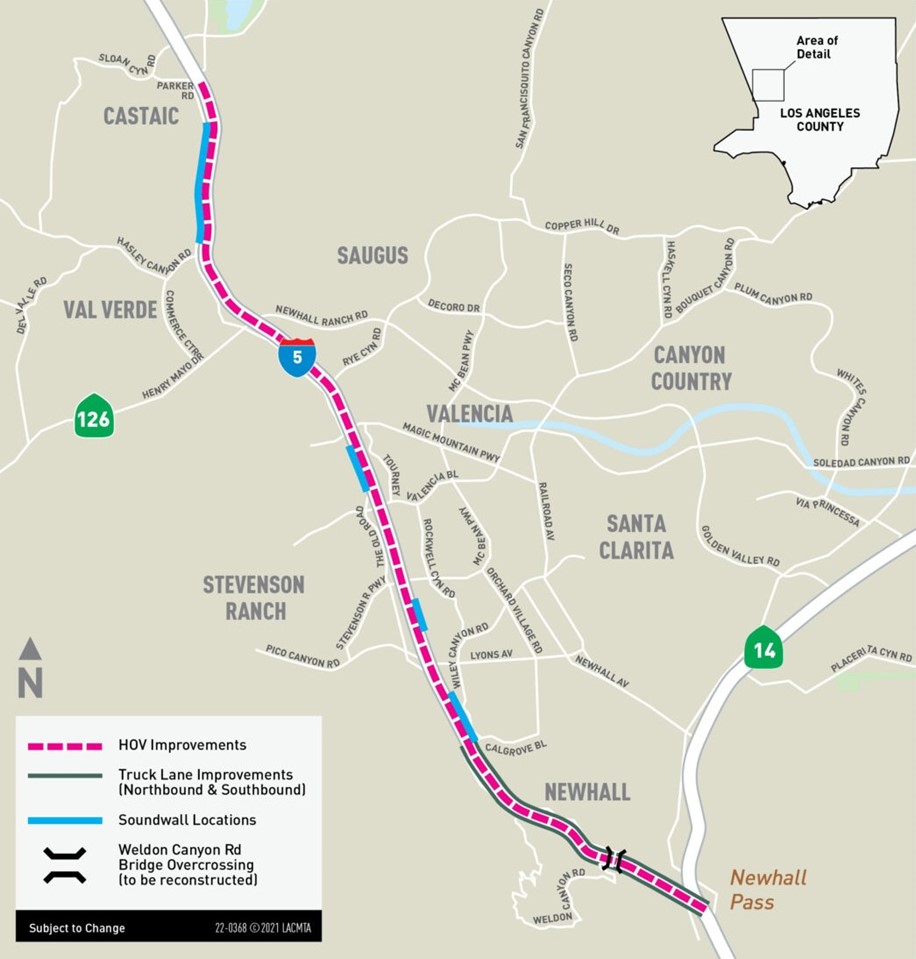

A massive project budgeted at $679 million, it encompasses the widening of I-5 between State Route 14 to the south and the Parker Road Interchange to the north. Covering 17 miles in total, 13.6 centerline miles of the median are to be widened to accommodate one new HOV lane in each direction, along with additional outside widening for auxiliary lanes.

Back-ups from, and safety issues related to slower truck traffic will be lessened through the incorporation of a northbound truck lane along I-5 from SR-14 to Calgrove Boulevard and a southbound truck lane from Pico Canyon Road to SR-14.

OHL-USA is performing the lane-widening and HOV-lane work, reconstruction of the bridges, earthwork, foundation construction, and retaining and barrier walls, along with the electrical work for the Intelligent Transportation System (ITS) improvements, which will include count stations, closed-circuit television (CCTV), a traveler-decision support system, and ramp metering.

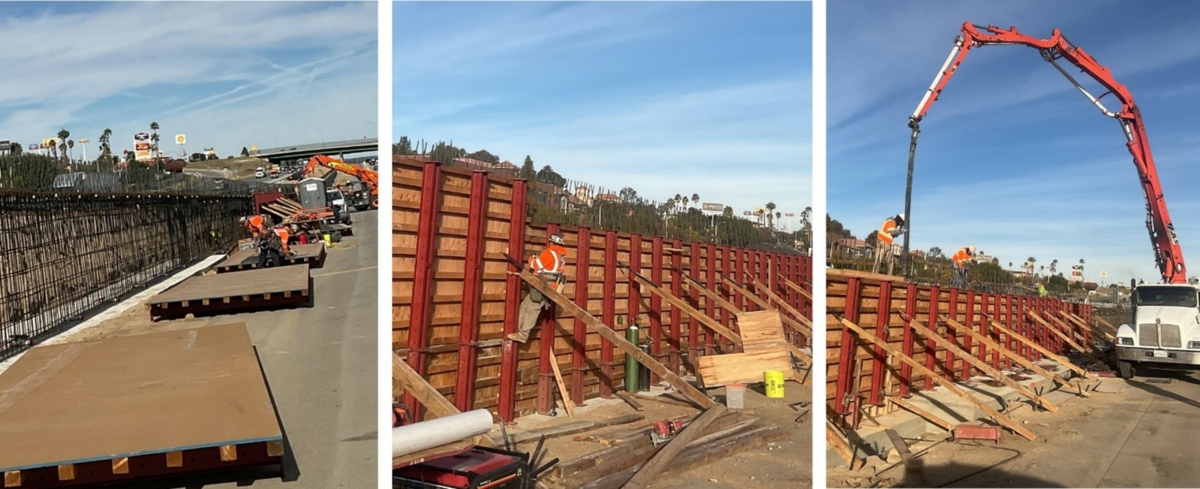

The prep, form, and pour operation that OHLA-USA employs in building the new retaining walls along Interstate 5.

New retaining walls will serve to avoid right-of-way impacts and minimize the project’s footprint width. Where median improvements are taking place, concrete barriers are being constructed. In addition, a Midwest Guardrail System is being installed, and new sound walls are being constructed.

Over the 17 miles of the project, seven bridge structures are being widened. They are: Gavin Canyon Undercrossing; Calgrove Boulevard Undercrossing; Butte Canyon Bridge; the I-5/SR-126 Separation at Magic Mountain Parkway; Santa Clara Overhead; Rye Canyon Undercrossing; and Castaic Creek Bridge. The Weldon Canyon Overcrossing will be reconstructed as well.

Paving has just begun, and Alex Medyn, Executive Vice President West Region of OHLA-USA, estimates that more than 172,000 cubic yards of Jointed Plain Concrete Pavement (JPCP) is going to be placed over the course of the project, with 71,000 cubic yards of Lean Concrete Base (LCB). An additional 57,000 cubic yards of concrete is going into the construction of the retaining, barrier, and sound walls, with 9,600 cubic yards going into the bridge expansions.

Currently, the project is at roughly 25% completion. Substantial Completion is projected for July 2026 and Final Completion on January 2027.

Sustainability on a Big Scale

OHLA-USA is working closely with National Cement and everyone involved is enthusiastic about the use of Portland Limestone Cement (PLC) in this project. The utilization of PLC will greatly reduce the embodied carbon of the in-place concrete, providing significant reduction in greenhouse gas (GHG) emissions. This is all in addition to the inherent sustainable benefits that concrete pavement provides, including a long life-span of 40 years and more, and extremely low maintenance needs over the life of the pavement.

OHLA-USA has set up an onsite batch plant for National Ready Mix on the project. According to National President Steve Lode, they will deliver the bulk cement to the batch plant from the National Cement plant in Lebec, using a fleet of Renewable Natural Gas (RNG) vehicles, which will further lower the carbon footprint of the project. “The partnership between OHLA-USA and NRM on this project defines what can be accomplished when teams collaborate and time is dedicated to seek solutions to today’s design challenges,” Lode emphasized.

The additional project concrete being supplied by National Ready Mix out of their Santa Clarita batch plant will also be delivered by RNG-powered vehicles; this time, concrete mixer trucks.

The partnering taking place on this project by OHLA-USA and National is a leading example of how the industry is committed to working together to lower the CO2 emissions of concrete pavement projects through mix optimization and innovative renewable fuels.