For a company to survive – and prosper – for more than 100 years, it takes a ton of grit, flexibility, and ingenuity. And often, a family legacy to carry it forward. Now in its second century of business, the George L. Throop Company definitely has all four.

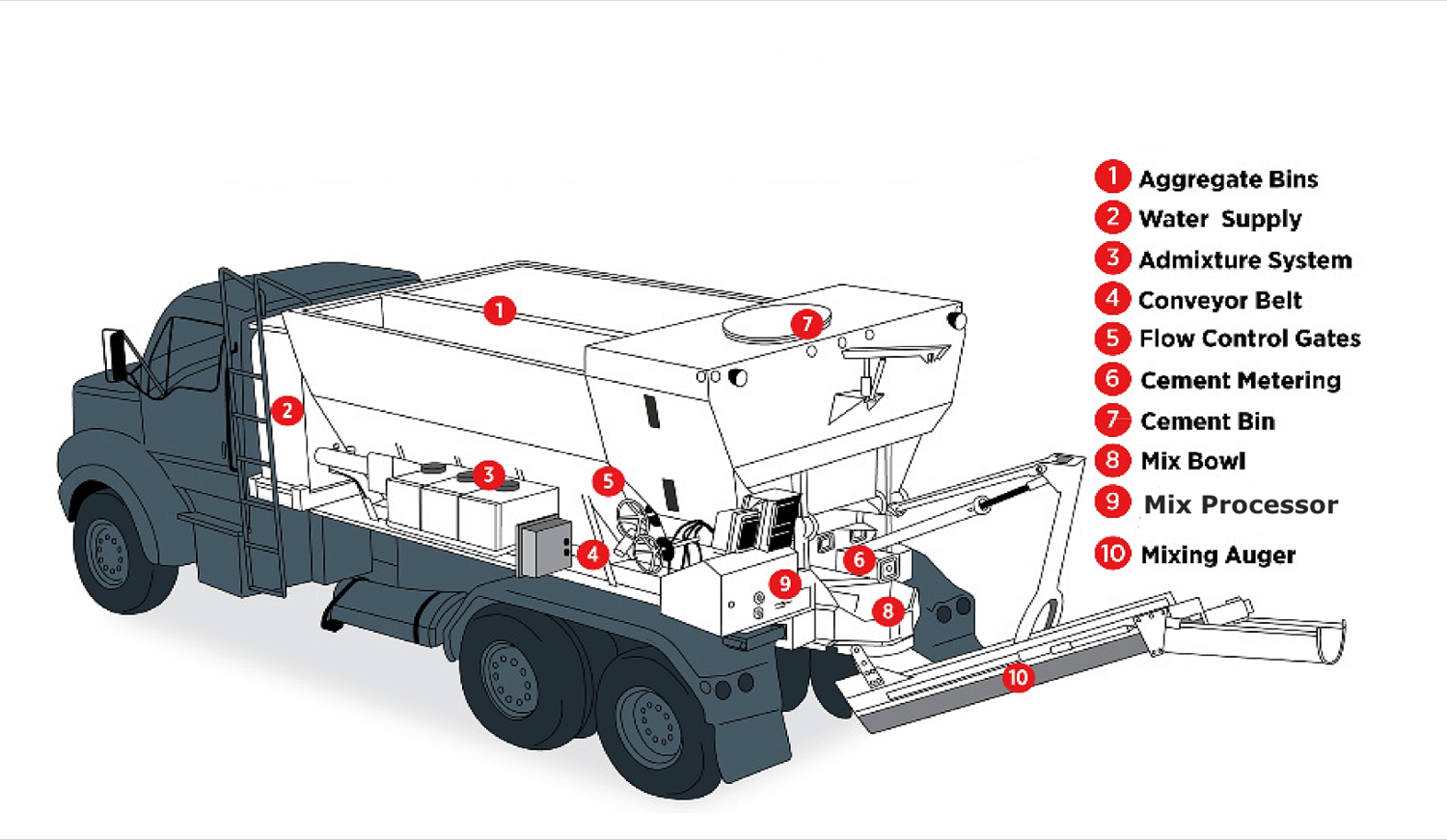

One of the 15 custom-built Volumetric Mixing Trucks owned and operated by the George L. Throop Company.

The firm was founded by George L. Throop, Sr. in 1921 in Pasadena, California; not as a concrete company, but a purveyor of coal and feed. Thanks to the strong economy of the Roaring ‘20s, Southern California’s building industry boomed, and the George L. Throop Company took advantage of it. Throop started carrying an inventory of building materials – cement, plaster, rock, sand, etc. – and they prospered. During this time of growth, George and Hilda Throop expanded their family as well, with a son, George, Jr., who grew up working in the family business.

Then the Great Depression hit in the ‘30s. George Throop, Sr. pared the company way down and focused primarily on selling the important commodity he started with – coal. The simplification plan worked and the company survived the depths of the depression.

With America entering World War II in 1941, George, Jr., who was attending USC, left the academic world and went to fight overseas. On the home front, George, Sr. faced another challenge. Building supplies became rationed due to the war effort and Throop’s business was drying up. Pivoting quickly once again, he parlayed a huge new warehouse that he had just built into a food dehydrating facility, which the U.S. Government used to create rations for the troops. Once again, the George L. Throop Company survived daunting economic conditions. Post-war, the company refocused their business back to building supplies and added Anti-Hydro waterproofing, concrete blocks, and other building materials.

Jeff Throop explains the volumetric mixing process to some of the attendees of the 20th Annual Nevada Infrastructure Concrete Conference who braved a brisk November morning last year to observe a demonstration mix and placement at the Q&D Quarry & Yard in Sparks, Nevada

Back from the war, George Throop, Jr. married in 1948, and he and his wife, Nancy, had three children – George III, Jeff, and Ann. The business continued to grow and the third generation of Throops joined the company, with George and Jeff Throop eventually serving as owners. Today, they are joined by the fourth generation of Throop to join the business, Adam Throop, who serves as Operations Manager for the company.

Just when everything was coming up roses in the late ‘60s, a different kind of curve ball was thrown at the company – twice – that forced them to relocate their operations. In 1968, the State of California condemned their property, ironically, to build a freeway, and five years later, their new property was once again condemned, this time by the City of Pasadena

Redevelopment Agency, to build the headquarters of one of the largest engineering firms in the nation. Fortunately, the third property that they moved to, on Fair Oaks Avenue in Pasadena, has proven to be a charm. Since they relocated there, the company has grown beyond their expectations.

NDOT Asst. Chief Materials Engineer Peter Schmalzer, left, listens intently as Jeff Throop details the fine points of the mixing adjustment mechanisms on the volumetric mixing truck.

Real Growth Comes Through Concrete

Though retail building supplies had been the mainstay of the company since its beginnings, the real growth of the George L. Throop Company began when they turned to producing concrete. They purchased a new trailer-haul concrete batch plant in 1979, and in 1987, they purchased their first volumetric mobile concrete mixer (think batch plant mounted on a truck chassis). The volumetric mixer is different from a ready-mix truck because the batch-plant-on-wheels is driven to the job site, and then the separated concrete components are mixed in real time and the concrete is immediately laid into place. The volumetric mixer carries a supply of rock, sand, and cement, which serves projects in remote locations very well. The volumetric mixer can also provide virtually unlimited amounts of concrete on site; additional materials can easily be loaded into the mixer as the demand continues. This unique amalgam has proven so successful for the Throop Company that they now operate 15 customized volumetric mixers.

Some volumetric mixers are truck chassis mounted and others are mounted on 40-foot trailers. Today, much of the company’s business involves producing Rapid Set concrete, cellular concrete, Type II concrete and custom concrete for a wide variety of applications, often on the fly.

Have Volumetric Mixing Truck, Will Travel

The unique load-and-go aspect of the Throop volumetric mixers makes the company the go-to resource for such projects as freeway panel replacement for Caltrans (opening up to traffic within two hours – sometimes less), airport runway repair, producing cellular concrete on site, and just about any job that’s not easily accessible by a ready-mix truck.

Freshly mixed concrete pours out of the chute of the Throop volumetric mixing truck at the Q&D Quarry & Yard in Sparks, Nevada.

When a project site is out-of-the-ordinary, remote or challenging, that’s when you definitely get the Throops’ attention. The Throop volumetric mixing trucks have produced concrete on far-away islands, mountain tops, on and around the ocean, rivers, lakes, and other marine locations.

For the recent 20th Annual Nevada Infrastructure Concrete Conference, Jeff Throop and his crew traveled from their HQ in Pasadena to the Q&D Quarry & Yard in Sparks, Nevada to perform a Volumetric Mixing Demo on November 3rd for members of the conference audience from NDOT, University of Nevada Reno, and a host of contractors and engineering firms.

The Q&D crew finishes the freshly placed concrete during the volumetric mixing demo on November 3, 2022. Five hours after casting, two cylinders were broken at 4,400 psi and 4,340 psi.

The Throop Company has an enormous depth and breadth of experience in concrete freeway slab replacement projects and has worked on almost every freeway or highway in Southern California. Throop trucks have poured Rapid Set concrete and Type II cement in Las Vegas, Lost Hills, King City, the San Francisco Bay Area, Sacramento, throughout Nevada, the State of Washington, multiple states on the East Coast, and other cities and states across the country. They always answer the call, no matter how far, and get the job done well.