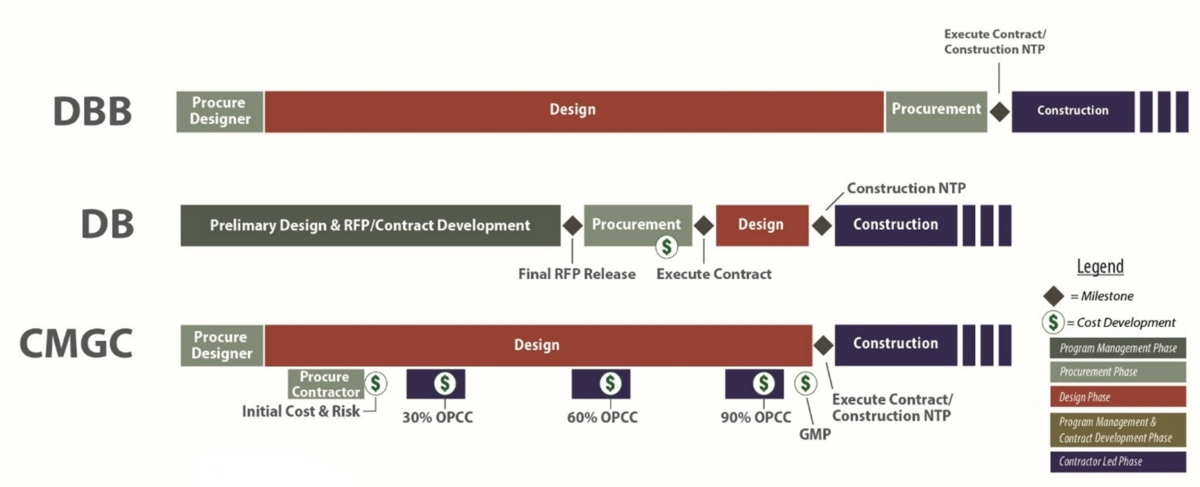

For new multifaceted projects, Design-Bid-Build – how the vast majority of the U.S. Highway System has been constructed – may not be the best contracting method today. There are two alternative contracting methods in use that offer greater benefits: Design-Build (DB) delivery, which came into use in the 1990s; and Construction Manager/General Contractor (CMGC), that began after 2005.

Let’s take a look at how these delivery methods differ, in relation to Caltrans projects.

Traditional Method

Design-Bid-Build – This is the traditional delivery method where Caltrans contracts separately for design and construction services, the bid is based on 100% complete plans and specifications, and design and construction occur sequentially. Design-Bid-Build is typically a unit-priced contract, but it can also include lump-sum items.

Alternative Methods

Design-Build –

Design-Bid-Build –

Caltrans contracts with one entity to complete the design and construction of a project under a single contract, typically a lump sum with allowances or unit cost items to address risk. Design-Build has been implemented using various procurement approaches, including qualified low bid (LB) and best value (BV).

Construction Manager/General Contractor –

Here, Caltrans hires the Construction Manager/General Contractor at the design phase to provide support, foster up-front communication and collaboration on innovations, cost and schedule savings, and constructability issues. Upon completion of the design or design packages, the contractor and Caltrans negotiate an Agreed-To-Price (ATP) for the construction contract, and then the construction manager acts as a general contractor to complete the project. The ATP contract will be either a unit price or a lump-sum contract.

Potential benefits of Design-Build and CMGC include project cost savings, lower operational and project lifecycle costs, improved constructability, enhanced innovation, reduced risk, expedited project delivery, and shortened construction schedules.

Another benefit of the CMGC program is the ability to provide greater opportunities for Small and Disadvantaged Business Enterprises (SBs and DBEs) to participate in Caltrans construction projects. The CMGC delivery method gives the contractor more time to reach out to the relevant subcontractors to achieve SB and DBE goals, unlike a Design-Bid-Build contract, which provides less than 20 working days to bid on the contract, including reaching out to the SB and DBE subcontractors.

With that list of advantages, it’s not surprising then to learn that Design-Build and CMGC are exponentially gaining in popularity and frequency of use.

Caltrans is an advocate of Alternative Procurement, and specifically CMGC. When he was serving as Chief, Office of Innovative Design and Delivery in 2015, Ray Tritt introduced CMGC as a new procurement method within Caltrans. When he moved from that post in 2020, he had pioneered 10 CMGC projects.

Following Ray, Belinda Hon stepped into the post of Chief, Office of Innovative Design & Delivery, and is also a strong proponent of CMGC. Since July 1, 2021, 40 CMGC Preconstruction Services contracts have been awarded, with contract amounts totaling more than $4 billion.

The CMGC contract for the Albion River Bridge Reconstruction Project in Mendocino County provides for expanded communication and innovation in determining the best methods to make this landmark structure safe and sound.

“CMGC provides a better understanding of the means and methods involved in a project,” Belinda explained. “CMGC takes the guesswork out of the process. Contractors have more time to accurately price a project, and risk is more clearly identified, and also shared.”

“There’s a greater schedule efficiency,” she continued, “and it has proven to be advantageous in the timing of permits and funding. Another benefit is that during the pre-con phase, all parties participate in Value Analysis and exploring innovations to determine the best way to build a project.”

Belinda emphasized that “CMGC helps us to build the projects in the best way possible. Everyone gets the chance to understand the goal, and together, all work toward the best possible outcome.”

It’s evident, based now on a broad range of experience, that bringing in all of the parties involved in building a concrete pavement project at the beginning ensures better communication, greater efficiency, and enhanced innovation. With those kind of benefits and advantages, Alternative Procurement may soon no longer be an alternative.